About Conference

Euro Ceramics 2020 cordially invites all the participants from all over the globe to attend “International Conference and Expo on Ceramics and Composite Materials” who scheduled during October 19-20, 2020 at Paris, France which includes prompt Keynote presentations, Oral Talks, Poster presentations, and Exhibitions.

The scientific event offers the best platform with its well organized scientific program to the audience which has interactive panel discussions, keynote lectures, comprehensive talks and poster sessions on the topics like Ceramic Engineering, Composite Materials, Glass Engineering and Science, Nanotechnology, Polymer Science and Engineering, Materials Science and Engineering, Surface Engineering and Ceramic Coating, Electro-magnetic and optical Ceramics and devices, Metal Oxides and Non Metal Oxides, Ceramography, Tissue engineering, Ceramics in Biology and Medicine, Crystallography, Sintering, Alloys, Ceramic Compounds: Ceramic Materials, Bio Sensors and Bio Engineering, Sol gels and organic chemistry, Bio-ceramics and Medical Applications, Superconductivity, Bio materials, Advanced Materials, Entrepreneurs Investment meet.

Scope and importance:

Ceramic engineering is a branch of engineering which deals with the science and technology of creating object from inorganic and non-metallic materials. It can be used in various industries. Ceramic engineering combines principles of chemistry, physics and engineering. Fiber-optic devices, microprocessors and solar panels are some examples of ceramic sciences applied to everyday life. As the applications of Ceramic material are expanded tremendously due to the recent advances in the field of medicine which include bio-ceramics and other, ceramic engineering is a booming field. Ceramics being a multi-billion dollar a year industry, ceramic engineering and research is an established field of science. Ceramics play an important in our day to day life; some of the items that include ceramic are glass light bulbs, jet engines, computers, cars and many household appliances. Ceramics used in Medicine, Construction, Electronics, Military, Optical fibers, Sports, Airplane, Transportation.

Why to attend?

Euro Ceramics 2020 will focus on different types of ceramics topics like Advanced Ceramics, Decorating Ceramics, Glass, Ceramic coatings, and Traditional Ceramics, Ceramics congress invites you for plenary talks, symposium, workshops, invited sessions and oral and poster sessions from various universities and associations. This is the best opportunity to the postgraduate students, academic researchers and industrial professionals who are interested in ceramic technologies for sustainable development.

Target Audience:

-

Metallurgical and material science Engineers

-

Engineering professors and faculty

-

Members of different material science associations

-

Junior/Senior research fellows of Materials Science

-

Research Scholars and students

-

Directors/CEO’s of Research-based companies

-

Scientists of Ceramics and Composite Materials and Materials Science Engineering

-

Research Professors and Research fellows of Ceramics and Composite Materials, Advanced Materials and Technologies

___________________________________________________________________________________________

Scientific Sessions

Ceramics

Ceramics is nothing but it is made up of metal or non -metal compounds that are first shaped hardened and then by heating on. Generally ceramic word has been derived from Greek word “pottery” which has been part high temperatures of the ceramic world. Nowadays ceramic has become one of the most commonly used name which includes glasses, advanced ceramics and cement systems .The major types of ceramics has been defined in three types: 1.earthenware 2.Stoneware 3.Proacline.

-

Earthen ware: It has been considered as the one of pottery. Which has been used for the table ware and as well as the decorative objects and more over it has been considered as the one of the part of the ceramics. Moreover the clay has been heated under the temperature of 1000-11500c.

-

Stoneware: In this phase the clay has been heated above 1200c until it turned into a glass. Because stoneware is a non -porous and glaze so it is applied only for the decoration purpose and more over it has been used for cooking, serving hot things .

-

Porcelain: It is very hard and translucent white ceramic .It has been arrived in china around 1600bc and above 600AD.To make the porcelain small amounts of glass ,granite and some minerals are crushed in the white clay.

-

Bone china: which is easier to make harder to chip and stronger than porcelain. It is made by adding ash from cattle bones to clay feldspar minerals and fine Silica sand.

Advanced ceramic materials has been used in day to day life in the form of fridge magnets to increasing wide range of industries. In medicine the advanced ceramics is also known as bioceramics which plays a vital role in bone substituents like knee and hip transplantations.

Ceramic and Composites

Ceramic and composites with one or more different phases that are having Nano-dimensions which are new generation of engineering materials that are having the potential applications in different areas. The typical micro structures of the Nano-ceramic composites which can be used as bulk materials and as well as different substrates for applications which mainly includes silicon, Nitrate-silicon, alumina silica carbide composites and Nano- ceramic-composite based coatings.

Composite Ceramic Materials

Ceramic matrix composites (CMCs) are a subgroup of composite materials and as well as a subgroup of ceramics. They consist of ceramic fibres embedded in a ceramic matrix. The matrix and fibres can consist of any ceramic material, whereby carbon and carbon fibres can also be considered a ceramic material.

Manufacture

Ceramic fibres

Manufacturing procedure.

Porous and Armour ceramics

Porous ceramics shows significant properties and features that other ceramics can’t exhibit. So that is why porous ceramics is found in different applications as final products in developing sites. Porous ceramics possess different physical properties such as good chemical and thermal stability, great fine specific strength and rigidity. The armour ceramics are used to protect the vehicles in the past and the strongest and lightest ceramic material is the boron-carbide. The materials that are used in armour ceramics are Carbon, Silica, Aluminium-Oxide. Boron Carbide is mainly used for ceramic plates in order.

Nanotechnology

Nanotechnology is a science, Engineering and technology that has been conducted at a small range is 1 to 100nm. Nanotechnology refers to the study of small things or tiny particles which can be used across different parts or various fields like biology, science, chemistry, physics, Material science and Engineering. The microscopes which are needed to see the small tiny things at the Nano scale. Now-a-days most of the scientists and engineers take the advantage of making the materials at the nano-scale in order to adopt the properties like strength , light weight , increased control of spectrum and great chemical reactivity from the large scales.

Sintering

Mainly it can be divided into mainly two types that is 1.solid state Sintering and 2.Liquid phase Sintering. The solid state Sintering occurs when the powder compact is taken in the solid state where as liquid phase sintering occurs when the powder compact is densified in the liquid state. Besides these solid and liquid phase sintering there are other types of sintering such as Transient liquid phase sintering and viscous flow sintering. The sintering process is widely used in the metallurgy process and as well as other ceramic components. Most of the industries use this process as trail and error method that provides less cost and more production. The Sintering process consists of other different types of models such as atomic scale model, Multi scale model including various different types of techniques for the computer Simulation.

Functional ceramics and Inorganics

It mainly comprises of electro ceramics, complex oxides, solid state materials ,inorganic 2D materials, inorganic porous materials and moreover it does not consists of materials for the energy applications, photonic, magnetic polymeric or composite materials those which are covered by the related areas .In the meantime we are going to support the world experimental and research that is going throughout the world wide. The functional ceramics are superionic conductors are nothing but cations and ions move easily in the presence of electrical field. There are various methods for the synthesis of inorganic materials to overcome many issues such as slow reaction, changing in the diffusion path lengths etc.

Ultra High Temperature and Ceramics

Ultrahigh temperature ceramics is a part of the re factory ceramics which define the stability at temperatures exceeding 2000C. This is also used in the environmental side which is mainly used to detect the extreme temperatures in the chemical reactivity, erosion attack etc. Using the melting temperature we are going to define only some materials under the ultrahigh temperature and ceramics and the materials that includes most of carbides, borides or nitrides of early transition elements

-

Borides that includes the ceramic like properties and also with high temperatures with high elastic and metallic properties such as high electrical conductivity and thermal conductivity. These properties makes the UHTC’s more attractive.

-

Carbides: Comparing to borides the carbides have high melting point and less electrical conductivity. Carbides have low oxidation resistance at interval temperatures due to formation of the co gas as one of the oxidation product. Carbides are typically used as the single phase ceramics in order to avoid the increase in temperatures,formation of reactions, solution formation and as well as formation of eutectics.

-

The development of the ultra-high temperature and ceramics is continued around and across the globe. while the significant progress has been made in order to understanding the fundamental microstructure processing elements further work indeed to develop the UHTC’s applications such as sharp leading and as well as aerospace wheels for the vehicles that are used in the space.

Surface Engineering and Ceramic Coating

The ceramic coating and surface engineering is a platform where to bring all scientists, research scholars, researchers to share their ideas, experiences on ceramic coating and research engineering. The surface engineering involves the altering properties of the surface phase in order to reduce the degradation over time and moreover it provides the material which is low of cost for the robust design. The surface engineering is used in various fields such as biomedical, power, electronic and so on. Coming to the ceramic coatings there are various benefits that this type of coating provides the substrate that is coated. The ceramic coatings are wide spread across various industries especially in the steel industry this is used to provide the properties of corrosion and wear protection and also the marine also use this property to define the resistance to corrosion in the presence of salt water along with non-conduction and wear protective.

Ceramics and Systems for Energy and Environment

It is mainly divided into following types such as advanced ceramics and systems, Design, development, processing and characterization of ceramic materials, Ceramic super capacitors, Materials and structures for solid oxide fuel cell and electrolysers. Micro porous amorphous, zeolite or hybrid organic-inorganic membranes, Production, Conversion and Storage.

Ceramic Engineering and Glass Engineering

Ceramic engineering is a branch of engineering that deals with the science and technology which is used for creating the object from organic and inorganic materials. It combines the principles of physics, chemistry and Engineering. The ceramic engineering is mainly used for the production of ceramic teeth, ceramic bones and other fibre optics. It is used in various fields such as medicine, construction, electronics, military, optic fibres etc.

Glass Engineering is a hard substance which may be transparent or translucent substance that is easy to break. It is manufactured by fusion process. Glass is used in construction and as well as in architectural purposes in engineering. The engineering properties that possess by the glass is listed are Transparency, Strength, Work ability, U value and Recycle property.

Bioceramics and Medical Applications

The Bioceramics is a material which is used for repairing or replacing damaged bone tissues. Basically physical, chemical and biological evaluation should be done likewise respectively long-term evaluation should be done if the ceramics is present in the bone tissue for a long time. But the long term evaluation is not easy to perform but it reduces the cost. The ceramic materials which have been used are not the same as porcelain type ceramic materials. It covers biological elevation for cancer therapy and as well as it is used in tissue Engineering.

Ceramic applications is the new platform which focus on the development of the ceramic components and their integrative design in complex industrial solutions. Recently the field has been include the studies of the single crystals and as well as fibres. In addition to polycrystalline materials the applications that has been overlapping and exchanging.

Crystalline Materials

A crystalline or a crystal is a solid material which has been comprised of the constituents such as atoms, ions, molecules which have been arranged in a highly ordered structure like a crystalline solid that exists in all directions. Many crystalline materials are centrosymmetric. Single element solids like fcc, bcc. And the diamond shape crystalline consists of the inversion symmetry. It covers the semiconductors, ferro-electric, optic-fibres.

Materials and Innovative Processing Ideas

Production root technologies have interdisciplinary nature including the board spectrum of the manufacturing of materials to module integration. The interdisciplinary plays a vital role. Production root technologies is nothing but the collection of six technologies that include the welding, forming heat treatment and as well as surface treatment. As the function of the products increases the importance of the technology concurrently growing.

Material science and Engineering

The interdisciplinary field of material science is referred to as material science and engineering. It is the new design which is used to discover the new solids and materials. The basics of the material science include the structure of materials and as well as their properties and determines the structure of a material and properties of the constituent elements, and are taken together which are related to the laws of thermodynamics and kinetics, govern a material's microstructure, and thus its properties. This is mainly used to understand ancient, phenomenal observations in metallurgy and mineralogy

-

Material Science and Engineering

-

Nano scale Materials and Nano Technology

-

Batteries and energy Materials

-

Metals , Mining, Metallurgy and Materials

-

Smart Materials

Electro magnetic and optical ceramics and devices

The electro ceramics is mainly used for the preparation of conductors, resistors, capacitors, microwave dielectric conductors etc. The electro ceramics has been used various different types of applications. In addition to these there are desirable levels of electrical properties, devices that have been manufactured from electro ceramic materials which also exhibit adequate levels of mechanical and other properties. Electrical Ceramics and Transparent polycrystalline materials as optical ceramics

Super conductivity

It is a physical property which is observed in certain materials where the electrical resistance vanishes and magnetic flux fields have been expelled. Any such type of material exhibiting these types of properties referred to as super conductors. Like ferromagnetism and atomic spectral lines, superconductivity is a quantum mechanical mystery. There are many different types in which they have been classified

-

1.By the ory of operation

-

2. By Material

-

3. By critical temperature

-

Response to magnetic Field

-

Most of the physical properties of the semiconductors vary from material to material.

Tissue Engineering

The tissue engineering is an important field which is mainly used to repair the effected tissue. Recently, it has been considered as one of the biomedical nanomaterial which plays a major role in tissue engineering as they better supports the tissue regeneration besides it also combines the principles of materials and cell transplantation of endogenous new generation.

1. Biosensors

2. Immunotherapy

3. Gene Therapy

4. Bio Artificial organs

5. Nanotechnology in Tissue Regeneration

6. Applications of Tissue Engineering & Regenerative Medicine

Ceramography

Ceramography has been evolved with the other branches of materialography and as well as with the ceramic engineering. It is often done qualitatively, for comparison of the microstructure of a component to a standard for quality control or failure analysis purposes. Three common quantitative analysis of microstructures are grain size, second-phase content and porosity whereas crystallography is a branch of science that deals with discerning the arrangement and bonding of atoms in crystalline solids along with the geometric structure of crystal lattices.

Advanced Materials and Technologies

It is mainly used to represent the appealing class of materials whereby the field of metal oxide nanostructured morphologies have become one of the most active research areas within the Nanoscience community. The main ability to manufacture ceramics with an intrinsic nanostructure is that which enables the resulting ceramic materials should be optimized for a specific purpose. It also covers Highly porous ceramic and metal materials, Composites based on shape-memory alloys, Design and manufacturing technology for ceramic and cermet composites with structural and phase transformations,.

-

Increased investment on the development of infrastructure

-

It also requires High production cost

Nano structured ceramics

It is mainly used to represent the appealing class of materials where the field of metal oxide nanostructured morphologies have become one of the most active research areas within the Nano-science community. The main ability to manufacture ceramics with an intrinsic nanostructure is that which enables the resulting ceramic materials should be optimized for a specific purpose. It also covers highly porous ceramic and metal materials, Composites based on shape-memory alloys, Design and manufacturing technology for ceramic and cermet composites with structural and phase transformations.

Electroceramics

The electronic ceramic materials are reviewed to check the behaviour of capacitors, thermistors, varistors, and other electro ceramic components. The progress on the miniaturisation of ceramic components leads to the development of multipurpose electronic packages containing the complex three-dimensional circuitry Besides a wide variety of smart sensors, transducers, and actuators are being constructed for the utilisation of composite materials in order to concentrate fields and forces.

Silicate Ceramics

The ceramics industry is at top position in producing unique design of high quality ceramic products such as tiles, sanitary ware, ceramics tableware, brick and roof tiles, and refractories. However, the silicate based traditional ceramic and construction materials industry needs to be being continuously evolve and adapt to the challenges that have been increasing competitively and gain sustainability in the industry. Consequently, considerable attention is required by the sector for the research and development in all aspects: from design to digital decoration, from new products to new applications, in the innovation of materials and the manufacturing processes, and to input from progress in many other fields of advanced materials in geo polymers.

Market Analysis

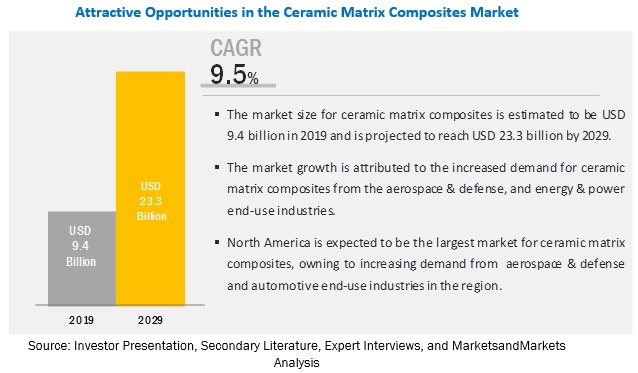

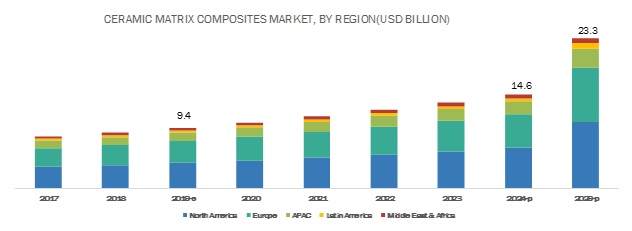

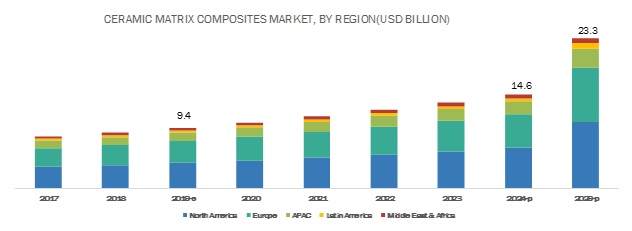

The global market for ceramic matrix composites is expected to grow at a CAGR of 11.4% from 2019 to 2026 and will reach US$ 11,516.1 million by 2026, reveals a new report added by Big Market Research . This report provides an in-depth analysis of the Global Ceramic Matrix Composites Market along with the current trends and future estimates to elucidate the upcoming investment pockets.

it helps in planning investments and capitalizing on market opportunities. Additionally, the research provides helpful study material for shareholders, investors, top market players, and new players to gain insights on current scenarios and form strategies to be adopted for the future.

Product Insights

Traditional product segment such as clay, silica, feldspar, and many more is projected to dominate the global industry of ceramics over the forecast period. Traditional product category largely finds its application in the manufacturing of tiles. Steady growth in the tiles industry is considered as the direct driver for the growth of the traditional product segment.

By End-Use Industry

Medical, Defence and Security, Environmental, Chemical, Others.

The major factors that are expected to be driving the CMC market are tighter government regulations concerning fuel efficiency, high demand from aerospace & defines, automotive, and energy&powerend-use industries, and ability to survive at high temperature.

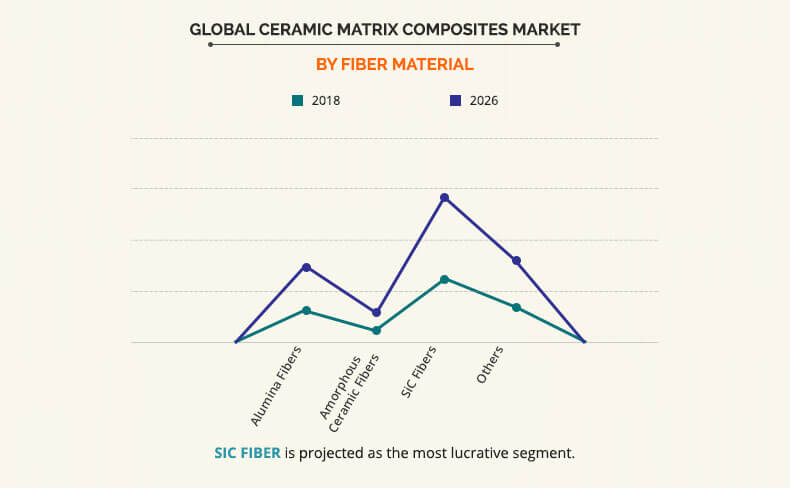

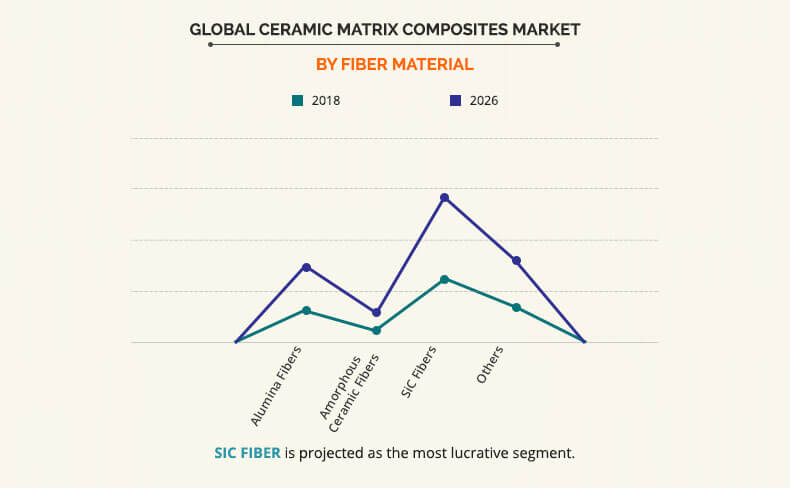

The ceramic matrix composites market was dominated by the oxide/oxide ceramic matrix composites segment, in terms of volume. This is due to the high demand for oxide/oxide ceramic matrix composites in aerospace, industrial, and automotive applications. Oxide/oxide ceramic matrix composites are considered as the material of choice in the aerospace, industrial, and automotive industries due to their low weight and high-temperature resistance properties. It is also widely used in industrial applications. They are less expensive than Sic/Sic ceramic matrix composites.As per fibre material, the SIC fibre segment accounted for the major share in 2018. This is attributed to the fact that silicon carbide fibre offers high stiffness, high chemical resistance, high temperature tolerance, and low weight as well as thermal expansion. Due to all these benefits, silicon carbide fibers are the clear choice for hot section components in the next generation of gas turbines. This in turn is anticipated to fuel the growth of the ceramic matrixcompositesmarket.

Ceramic Matrix Composites Key Market Segments:

Silicon Carbide Reinforced Silicon Carbide (SIC/SIC)

-

Carbon Reinforced Carbon (C/C)

-

Oxide–Oxide (Ox/Ox)

-

Others (Silicon Carbide and Carbon (SIC/C))

By Fiber Type

-

Short Fibre

-

Continuous Fibre

By Fiber Material

-

Alumina Fibers

-

Amorphous Ceramic fibres (RCF)